Equipment Packaging

FSM offers a complete, one-stop source for equipment packaging, machinery upgrades and replacement parts. We create and deliver packaging equipment that performs to unique production goals, using the most modern and reliable techniques available.

Our services also provide expertise across an endless variety of industries, including healthcare, cosmetics, food & beverage and consumer goods.

Contact Our Shrink Packaging Department

Ivan Simic

Machinery Parts Coordinator/Designer

Packaging Equipment

Innovative designs available from FSM are the Positive Overlap Sealer, Stand Alone Lap Sealer and the Side Sealer II. A new and innovative method of sealing shrink film on automatic form, fill and seal equipment. Designed to replace static sealing drag block or wire systems.

- Side Sealer II

- Positive Overlap Sealer

- Stand Alone Positive Lap Sealer

- The DuoSeal™ System

- Pin Perforation System

- Complete Top Sealbar Assemblies

Side Sealer II

- Customized seal width (up to 1/8’)

- Separate sealing and trim operations

- Band exhibits long life in the field

- Lubrication free timing belt

- Hardened steel knife & anvil shafts

- A fully self-contained temperature control box

- An off-the-shelf Cal 3200 series temperature controller uses PID logic for very accurate control.

The Side Sealer II can be used in conjunction with the DuoSeal® cross seal system.

Positive Overlap Sealer

- Simple to change the heated ban

- Band exhibited long life in field use

- The Sealer is a direct replacement for a static unit or the drag system.

- Easy to install and service.

- A fully self-contained control box allows an easy retrofit without extensive machine wiring changes.

- An off-the-shelf Cal 3200 series temperature controller uses PID logic for very accurate temperature control.

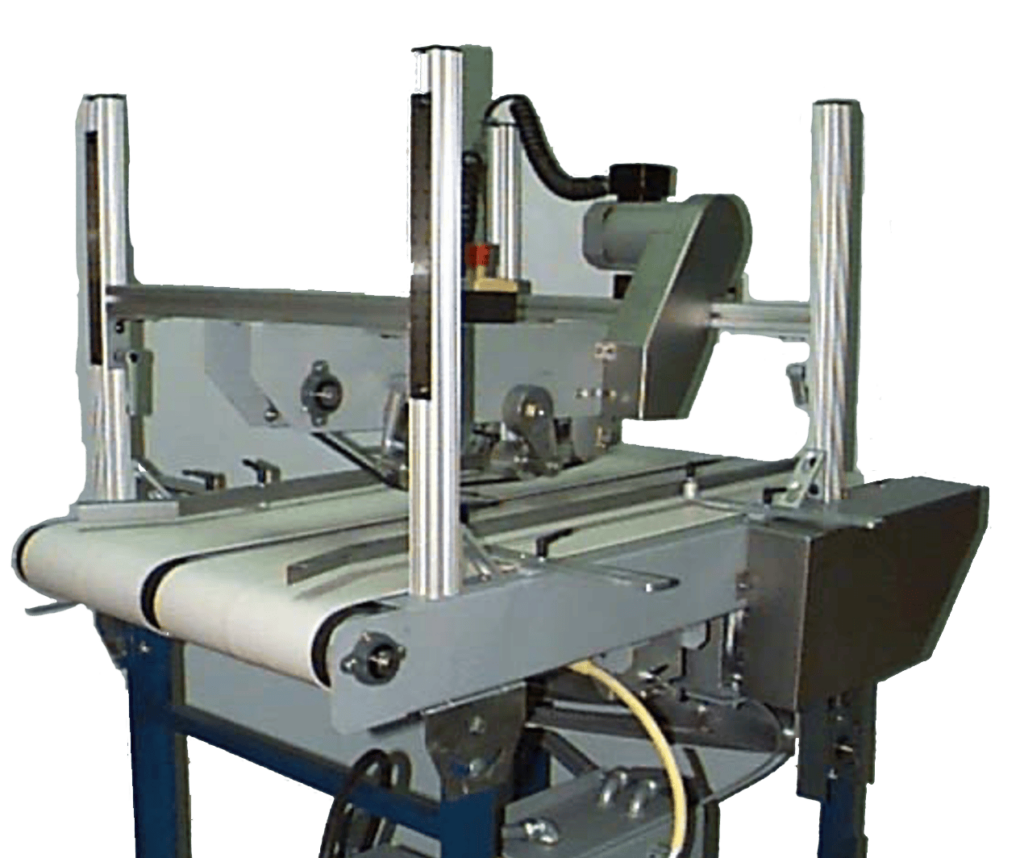

The Stand Alone Positive Lap Sealer

- This versatile add on unit can be inserted between the sealer and the tunnel or between the tunnel and the take-away conveyor.

- Used for machines that has static or drag systems, where conversions are not practical.

- Fast, the sealer is rated at 200 linear feet per minute and can take packages up to 11 1/2″ tall and 20″ wide.

- Belt speed is adjustable to match line speed.

- An optional driven & synchronized upper hold down unit will keep light packages and tall packages in constant contact with the 15″ long Stainless Steel

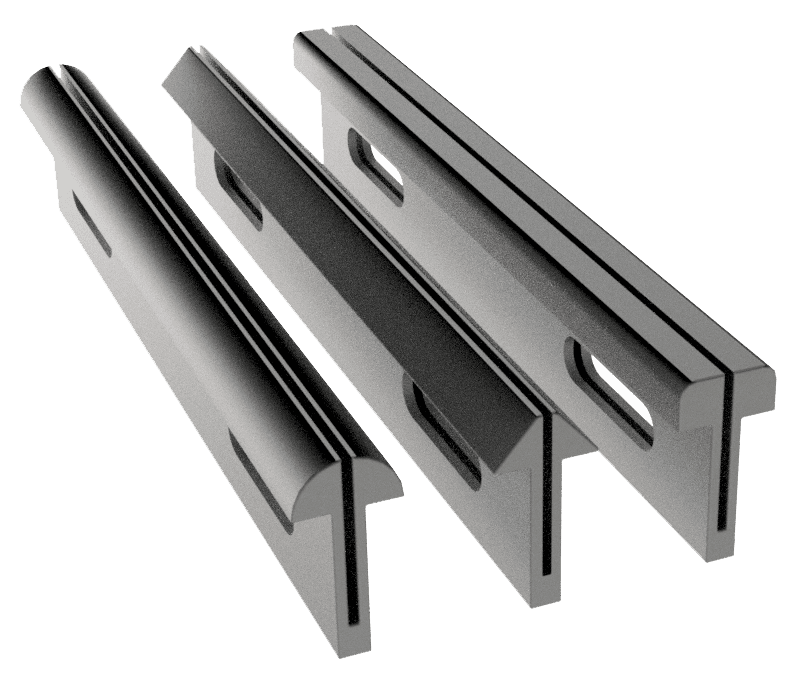

The DuoSeal™ System

- The system was designed for automatic form/fill/seal machines, as well as, automatic and semi-automatic L-Sealers.

- Nearly 20 years of field service

- Optimum sealing versatility, low start-up cost, low operating cost and low maintenance cost.

- Operates at significantly lower temperatures.

- Utilizes precision extrusions, unique coatings, custom heating elements & 3 specifically designed inserts.

- All 3 interchangeable inserts are capable of using the same cutting blade.

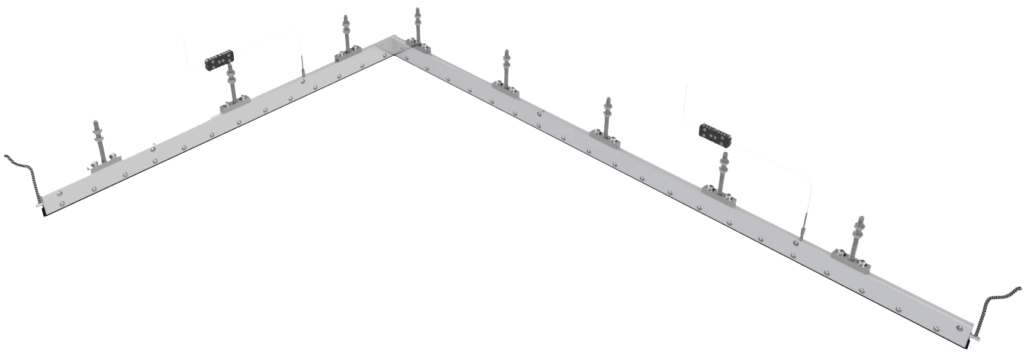

Pin Perforation System

- A low cost, high quality pin perforator system.

- Consists of an extruded perforator roll with six pin holders that have two pins per holder.

- Twelve perforated holes in the web of film per revolution.

- The Allen screw in the middle of the holder allows for quick adjustment of the location and amount of holes.

Complete Top Sealbar Assemblies

- Replaceable seal surfaces

- Uniform heated SealBars

- Adjustable mounting to allow for expansion when operating at high temperatures.

- Probe type thermocouples that are inserted into the bar giving accurate temperature readings.

- Our Phenolic Clamp Shields allow us to narrow our sealing area, resulting in closer package seals.

Machinery Upgrades Benefits

Conversion from hot wire to J.E. Fifer DuoSeal

- Eliminate smoke and odor

- Eliminates film residue on wire

- Reduced maintenance frequency

- Less downtime and cost when maintenance is required

- Increase operating speed

- Lower operating temperatures

- Better temperature control and more uniform profile

- Inserts available for different packages and materials ( co – packers )

- Inserts easily replaceable with minimum downtime if mechanical damage occurs

- More consistent seals, no pinholes, angel hair, etc.

Conversion from hot knife to J.E. Fifer DuoSeal

- Eliminate smoke and odor

- Eliminates film residue

- Reduced maintenance frequency

- Less downtime and cost when maintenance is required

- Lower operating temperatures

- Better temperature control and more uniform profile

- Inserts available for different packages and materials ( co – packers )

- Inserts easily replaceable with minimum downtime and less costly than complete hot knife assembly if mechanical damage occurs

- Lower inventory costs for spare parts, inserts, knives, and heaters usually available overnight

Conversion from heated wire side sealer to J.E. Fifer Side Sealer II

- Eliminate smoke and odor

- Eliminates film residue on wire

- Reduced maintenance frequency

- Less downtime and cost when maintenance is required

- Better temperature control and more uniform profile

- Less downtime and cost when maintenance is

- required

Lower operating temperatures - Seal size can be changed to accommodate wider range of package sizes

Conversion from static overlap to J.E. Fifer Positive Overlap Sealer

- Permanent seal

- Better accommodates unsupported seal areas on packages

- More forgiving with web variability

Conversion from drag wire or block to J.E. Fifer Positive Overlap Sealer

- Better package appearance

- More consistent seal

- Lower operating temperature

- Eliminates residue and build-up

Conversion from hole punch to J.E. Fifer Pin Perforator

- More versatile

- Improved package appearance and cleanliness

- No contamination of product or machine with punch outs

- Reduced maintenance

- No power required

- No timing with machine required

New Innovations

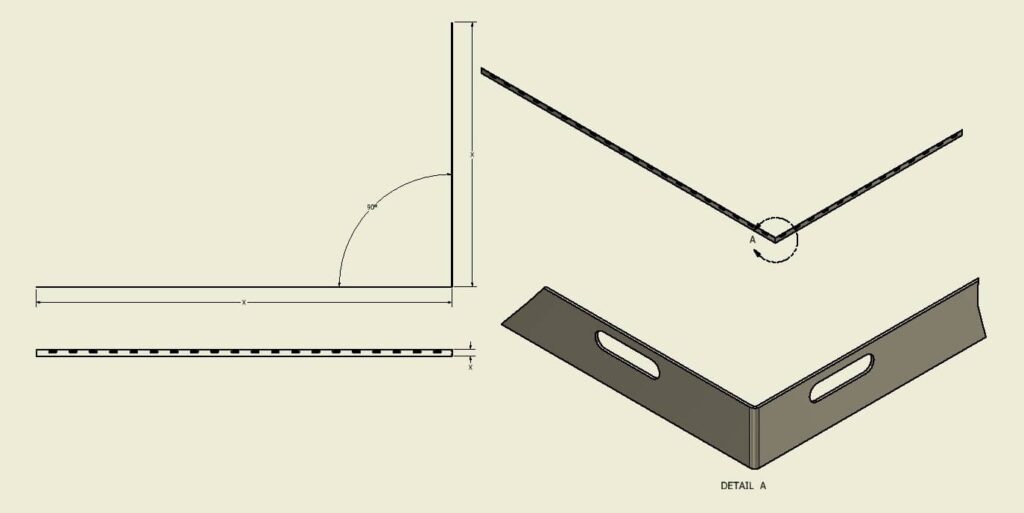

Radius Knife Blade

The Radius Knife Blade, now available on all Automatic L-sealer kits available from FSM. Created to control those annoying corner rips on Automatic L-sealers, the radius corner eliminates the sharp corners and subsequent tear on many of today’s Sealers. In a typical selvage wind system, the scrap area of the film is pulled when advancing. This can cause a tear at the intersection of the front and cross seals, The Radius Knife Blade helps eliminate that propagation.

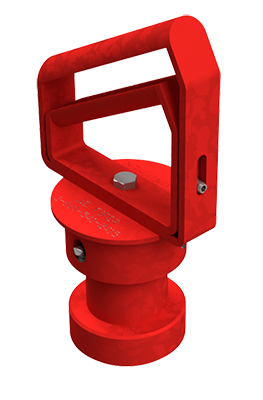

The Gripper

If you work with heavy rolls of film, foil, paper…etc., and if it comes on a 3” diameter core, let the “Gripper” make your work day easier. Constructed from anodized aluminum and stainless steel, the Gripper is made to last. Just place the cylinder body in your roll core and pull up on the handle. As the inner handle contracts 3 spring loaded pins securely grip the inner portion of the core.

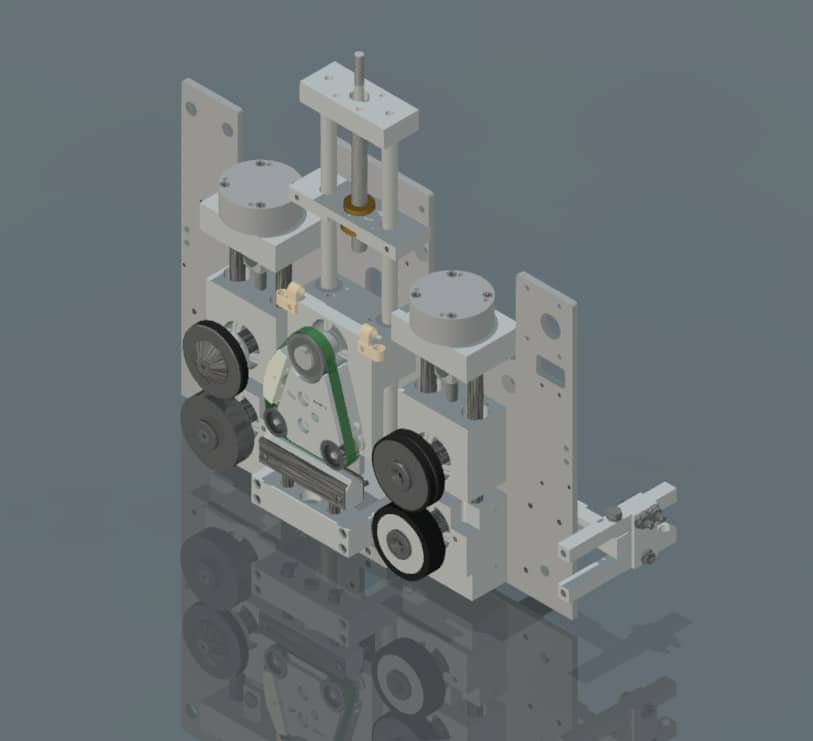

Portable Duo-Seal Unit

The Duo-Seal system is a “Patented”, versatile seal system that will allow you to seal all types and brands of shrink films by simply changing an insert. It will also allow you to vary the width of your seal by using any of four different style inserts we manufacture.

This handy unit will allow you to make product samples right in your customer’s plant without having to make time consuming setup changes to their production machines.

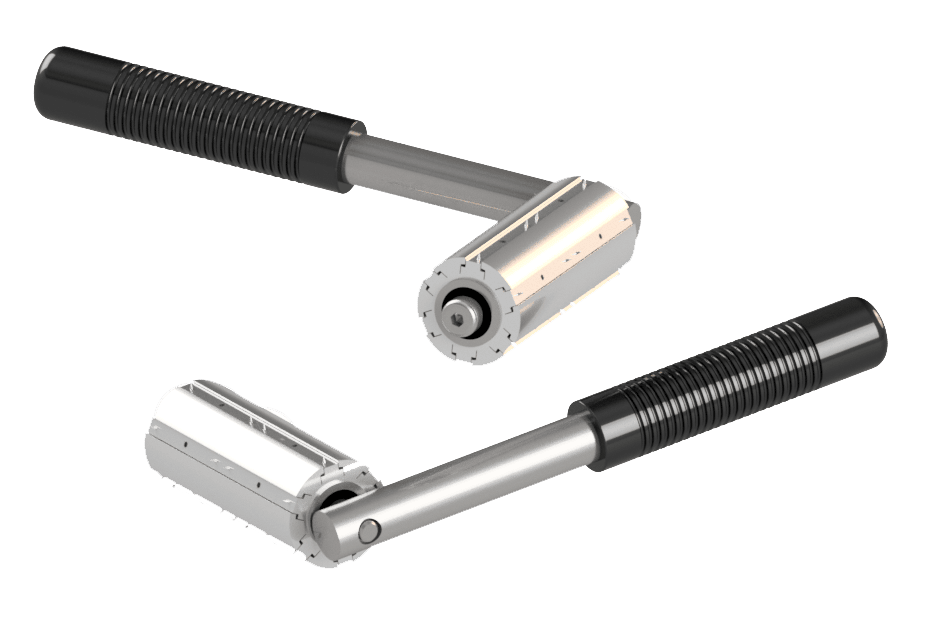

Hand Held Pin Perforator

We have incorporated our standard film perforating roller system into a convenient hand held unit. The Hand Held Pin Perforator comes with 12 T-Slot pin holders that fit into the 4” long perforator roller. It can also be easily mounted to a production machine using a simple design bracket and shaft collar system.

Side Sealer IV

Coming Soon!

Spare Parts

In the demand-driven world of manufacturing, spare parts are vital assets for maintaining productivity.

Having a piece of machinery down is never convenient, and without the right parts on hand, the length and impact of the downtime can quickly go from bad to worse. When you do have a need for spare parts, FSM is here to assist you as quickly and efficiently as possible.

Contact Us For Pricing and Availability

- Felt Pads (Various Thicknesses and Widths) in 6 ft. rolls

- Silicone Pads (Various Thicknesses and Widths) in 3 ft. rolls

- Silicone Pads w/ adhesive, 1/8” Thick (¾” & 1” wide) in 30 ft. rolls

- Silicone Drive Bands for Side Sealer units

- Sealing Bands for Side Sealers, Bottom Lap Sealers & Stand

- Alone Bottom Lap Sealers

- Bands are available in Standard or Teflon Coated

- Thermocouples (“J” Type) various terminations and connectors

- Heating Elements (1/4” Diameter) Cartridge & Tubular

- Various voltage, wattage, & lengths

- Cutting Blades (for all our Duo Seal Systems)

- Cutting Wheel (for Side Sealer units)

- Sealing Inserts (Mushroom, Arrow, Pancake, & Poly)

- All replacement sealing system Items & much more.